Manual: 5. Intelligent Health Monitor (IHM)

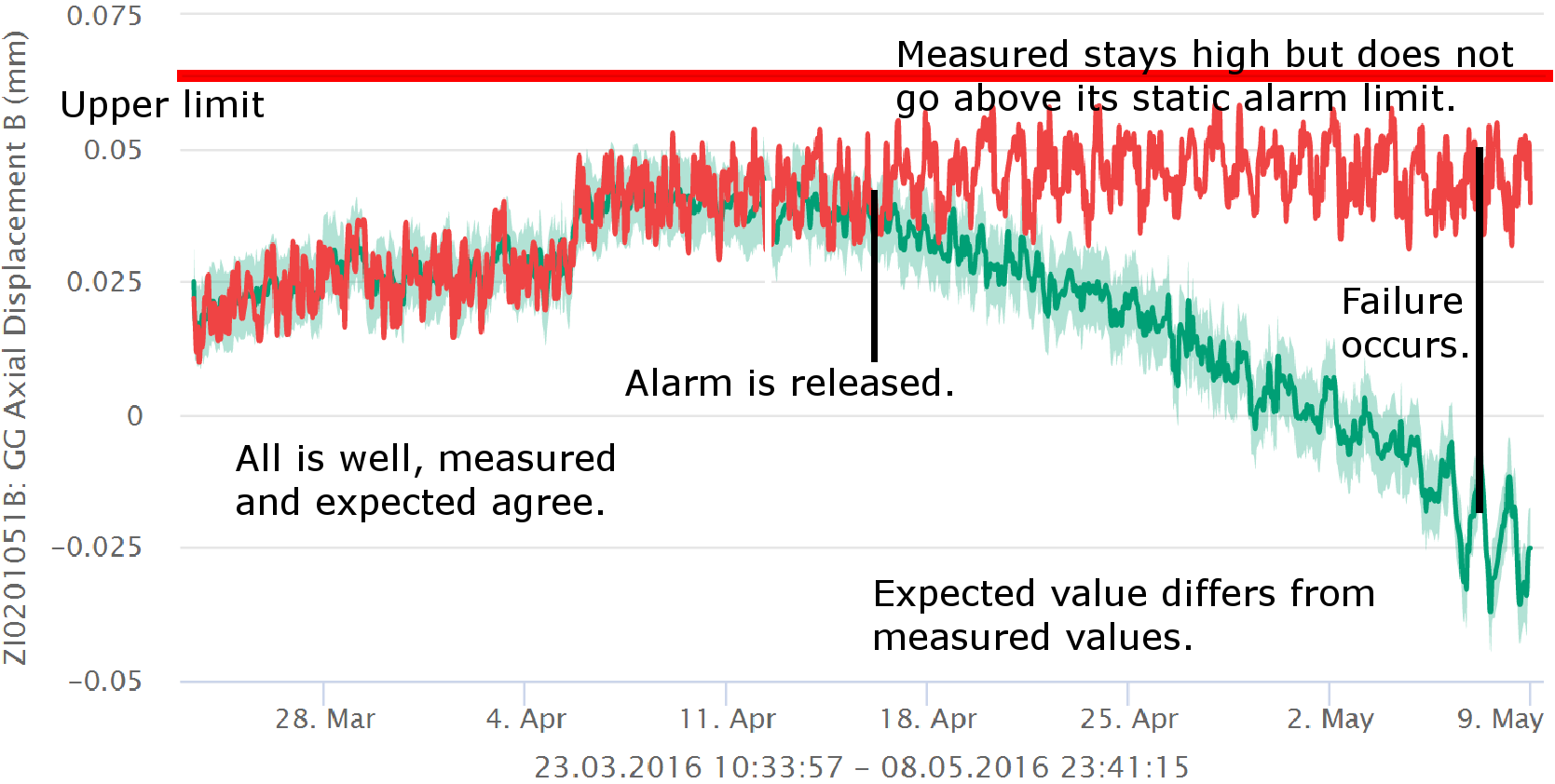

The Intelligent Health Monitor (IHM) makes condition monitoring smart by bringing it into the age of machine learning. Normal condition monitoring suffers from giving false alarms, not alarming all bad conditions, and requiring significant human expertise to set up and maintain. IHM solves all three of these problems by providing effective, efficient and accurate methods to detect equipment health. This is done by changing the definition of health from human specified limit values for each tag separately to a holistic form based on the past performance of the equipment.

Unhealthy states are detected because the combination of various measurements is taken into account by the holistic modeling approach. For example, temperature, pressure and rotation rate give valuable information about whether the vibration is acceptable or not. Due to that approach false alarms are also avoided. As the method is based on historical data, maintenance engineers no longer have to specify, maintain and document alarm limits.

As a result of the increased reliability of health detection, the availability of the equipment and thus the plant increases. With the increased availability, the effective production capacity of the plant improves. Due to being able to proactively maintain the equipment, maintenance can increasingly be planned and thus becomes less expensive. As the equipment no longer fails but can be proactively repaired, collateral damage is avoided and significantly lowers maintenance expenditure.